1. Raw materials of various specifications purchased by the company.

2. Conduct material test on raw materials with spectral analyzer, and print out material test report for backup.

3, With blanking machine for raw material cutting.

4. Inspectors check the cutting diameter and length of raw materials.

5, Forging and pressing workshop for raw materials forging and pressing molding processing.

6. Inspection personnel conduct various size inspection on the blank forming.

7. The workers are cutting the blank waste edge.

8, Sandblasting workers on the surface of the blank.

9. Inspection personnel conduct surface treatment inspection after sandblasting.

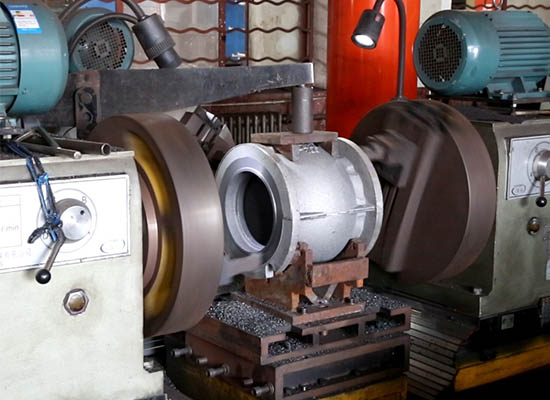

10, Workers for rough machine processing.

11, Valve body sealing thread processing — the staff in the processing since the inspection

personnel of the product after the processing of the product inspection.

12, Valve body connection thread processing.

13, Hole processing.

14,Inspectors conduct general inspection.

15. Qualified semi-finished products are sent to semi-finished products warehouse.

16. Electroplating semi-finished products. Inspection of electroplating surface treatment of semi-finished products.

18, All kinds of accessories (ball, stem, seal seat) inspection.

19, Final assembly workshop for product assembly – assembly line inspection personnel on the product inspection.

20. After assembly, the products are subjected to pressure test and drying to enter the next process.

21, The final assembly workshop for product packaging —- packaging line inspection personnel on the product sealing, appearance, torque inspection. Substandard products are never allowed to be packed.

22. Qualified products are bagged and sent to finished product warehouse.

23. All inspection records will be classified and stored in the computer for immediate reference.

24. Qualified products are sent to home and abroad through containers.

Post time: Sep-22-2021